- Air Homepage

- Alberta Air Quality

- Continuous Emission Monitoring Systems

- Cems Continuous Emission Monitoring System

CEMS continuous emission monitoring systems - Quality Control, Stratification, and Definitions

Learn about CEMS Continuous Emission Monitoring Systems with this guide that clarifies definitions, introduces you to how to conduct tests of gas stratification, and goes into some detail about quality control of components after replacement. From checks of accuracy under zero-emission conditions to Cylinder Gas Audits, this comprehensive resource makes sure this set of data is accurate.

Master Emissions Monitoring for Cleaner Compliance with CEMS - Imagine unlocking the code to emissions mastery, where a single miscalibrated sensor could spell regulatory doom, but one smart audit turns chaos into clarity. This guide gives you the tools to protect your operations and the planet-one precise reading at a time-by decoding jargon, nailing stratification tests, and busting bias.

Find out how to ensure a consistent flow-to-load ratio, which is essential for smooth operations. This guide simplifies CEMS practices, which can be quite complex, helping you maintain accuracy, meet regulatory standards, and protect the environment.

This page summarizes the technically-minded appendices of the Alberta CEMS code. You can view the original document here.

Here are some more details about Continuous Emission Monitoring Systems. Summaries are provided for main parts of the Code.

Section 1 - Introduction

Sections 2 to 4 - Details on analyzers

Section 5 - Info about CEMS equipment

Section 6 - Quality Assurance and testing

Section 7 - Details on accuracy for monitoring systems

Sections 8 to 10 - Monitoring, reporting and prediction

Appendix A - Definitions and acronyms for CEMS continuous emission monitoring systems

Various terms used in the CEMS Code are defined here:

- Alberta Stack Sampling Code: How to take smokestack samples in Alberta.

- The Alberta Air Monitoring Directive (AMD): Alberta's air quality rules.

- Approval: Permission granted under the Environmental Protection and Enhancement Act (EPEA).

- As found: A device's initial measurement value before calibration.

- As Left: Calibrated (adjusted) measurement value.

- Standard-setting organization ASTM (American Society for Testing and Materials).

- A bias is when measurements are consistently too high or too low.

- A Bypass is a secondary path for emissions during certain operations.

- Calibration: Adjusting a measurement device to match a reference.

- Calibration adjustment: Fine-tuning a device's output.

- The Continuous Emission Monitoring System (which is what CEMS stands for) measures and records emissions continuously.

- Alberta CEMS Code: CEMS continuous emission monitoring system Rules and guidelines.

- The CEMS User Manual: How to report data electronically.

- Certified Reference Material: Calibration gas with known properties.

- CGA (Cylinder Gas Audit): Used for testing the monitoring system with known gas concentrations.

- Carbon dioxide (CO2): a common greenhouse gas.

- CEMS Continuous Emission Monitoring System: Equipment that tracks emissions continuously.

- Taking corrective action: Fixing issues that may cause non-compliance.

- Cylinder Gas Audit (CGA): A method of testing the monitoring system with certified gases.

- The Data Acquisition System (DAS) receives, computes, retains, and reports measurement data.

- Day: Calendar day.

- Emissions diluent gas: Major component or used to dilute emissions.

- EPEA directors are people who are designated as directors.

- Flowing downstream: in the direction of effluent.

- Analyzer drift: Gradual changes in output unrelated to input.

- Analyzer with multiple measurement ranges: A dual-range analyzer.

- Effluent Stream: Gases released by industrial operations.

- Emission: Release of substances into the atmosphere.

- EPA (United States Environmental Protection Agency): U.S. agency that protects their environment.

- Protocol Gas: EPA-approved calibration gas.

- Environmental Protection and Enhancement Act (EPEA): Alberta's environmental law.

- Analyzers locations in stacks are determined according to their equivalent diameter.

- Flow Analyzers measure emissions flow.

- Full Scale (FS): The upper limit of an analyzer's range.

- Gas Analyzers measure gas concentrations.

- Back-up data source: A system that stores data in case the primary system goes down.

- An hour is a clock hour.

- A place where specific activities (as listed in the Alberta outlined in the Activities Designation Regulation, the AR 276/2003) is an industrial operation.

- In-Situ: Analyzers that measure gas concentration within a stack without sampling.

This machine measures air emissions

This machine measures air emissions- Stack opacity: How much light gets blocked by visible emissions.

- CEMS with interference rejection can measure a specific gas without being affected by other gases.

- Invalid data: Data that doesn't meet quality standards.

- Like-kind: Using the same type of analyzer as the primary.

- Linearity: How consistently a CEMS responds to changes in concentration.

- An industrial process unit's load is its production rate.

- Detection Limit: The lowest value a device can measure.

- A major component replacement involves changing a part that could affect the system significantly.

- Replacement of a minor component: Changing a part that doesn't affect performance much.

- Missing Data Estimation: Guessing values for periods with no reliable data.

- "Month" Calendar month.

- NIST = The National Institute of Standards and Technology.

- Nitric oxide (NO) and nitrogen dioxide (NO2) are nitrogen oxides (NOx).

- Non-compliance: Not meeting CEMS Code or other requirements.

- A normal operation is when everything works as it should.

- Oxygen is O2.

- Sensitivity to orientation: How much a flow monitoring system is affected by its orientation.

- Operational Test Period (OTP): A specific testing period.

- Out-of-Control: When the CEMS doesn't meet specs, so data isn't reliable.

- Path-system or path-type: CEMS that measures gas concentration along a path.

- Process data is used to predict emissions with PEMS (Predictive Emission Monitoring System).

- Person Responsible: Owner or holder of an EPEA approval.

- point CEMS or point system: Measures gas concentration at a single point.

- Parts per million (ppm): Unit of measurement.

- A predictive emission monitoring system predicts emission concentrations or rates.

- Primary: A source's original, certified analyzer or CEMS.

- PS - Performance Specification: CEMS performance specs.

- Emissions are removed from the stack in purge mode.

- It's all about QA, QAP, and QC (Quality Assurance, Quality Assurance Plan, Quality Control).

- Quality Assurance Plan: Administrative activities and documentation intended to prevent mistakes or problems.

- Data is quality assured if you can trust from it, being from a well-functioning CEMS.

- Controlling the quality of a product or service makes it comparable with standards.

- Quality System is for ensuring quality in an organization's processes.

- A quarter is three months in a row.

- A quantity's range is the difference between its upper and lower limits.

- The RATA (Relative Accuracy Test Audit) checks accuracy.

- Analyzer raw data: Original values.

- Redundant Backup analyzer that continuously records data in case the primary system fails.

- Reference Method is specified in the Alberta Stack Sampling Code or the Environmental Protection Agency.

- A reference value is a known concentration of a test gas or a known value of a reference device.

- Regulations: Rules that apply to CEMS.

- RM (Reference Method): Sampling or analysis method.

- Sulfur dioxide (SO2): A specific substance.

- The source operating is anytime effluent is discharged, even during start-up, cool-down, or other processes.

- Span: Analyzer output range and drift.

- As a reference, we use Standard Pressure (1 atmosphere) and Standard Temperature (298.15K).

- Temperature-responsive Span Drift, Temperature-responsive Zero Drift: Changes in analyzer output when the temperature changes by 10 degrees between 5 and 35°C.

- When the primary analyzer goes down, a third party runs a temporary backup system called Third-party short-term continuous monitoring.

- CEMS test gas: Reference cylinder gas.

- Measurement units of the Analyzer, measurement units of the Standard may be different.

- Upstream: Against the flow of effluent streams.

- Validation: Confirmation that specific requirements are met.

- Reliable data may meet specific criteria: Valid Data, such as Valid Hour, Valid Interval, Valid Partial Hour.

- Verification is checking the output of a device or system against a reference.

- "Year" is a calendar year.

- Zero: Analyzer's response compared to an input value of zero.

These definitions cover most of the key terms. See Appendix A of the document for more details on the complete list.

Appendix B - Stratification Test

This procedure measures how gases spread inside a duct or stack. Gases don't always mix evenly, so this test checks if the gases are mixed well.

Here's how:

- At least nine sampling points are needed. Stack them in a balanced pattern, following specific guidelines.

- Measure gas with two analyzers that work the same way. On one, measure the gas concentration at each sampling point, and on the other, at a fixed spot (usually in the middle).

- Find out how gases are spread at each point using the formula (Equation 9). You might have to redo the test when conditions are more stable if the concentration at the fixed spot changes a lot.

- Make sure you measure the gas concentration again after all measurements. When things are more stable, retest if it's very different from the first measurement.

- Gases are evenly distributed in the stack during the test. To get accurate readings, you might have to move the gas monitoring equipment.

It's like checking if the air in a room is mixed well or if there are pockets of strong smells. You might need to move stuff around to make sure the air is clean.

Appendix C - Quality Control Checks After Minor Component Replacements

You should perform some quality control checks when you replace, repair, or do routine maintenance on CEMS continuous emission monitoring systems. Checking emissions is important to make sure they're accurate. These are some examples of components that might need replacing or repairing:

- Circuit boards, power cords, lamps, valves, and filters are minor parts.

- Pumps or parts for analyzers.

- Circuitry or wiring in the CEMS shelter.

- Gas analysis parts like capillary tubes, O-rings, and moisture removal systems.

- Analyzer components like ozone generators, reaction chambers, and NO2 converters.

- Fuel flow meter parts or gas flow control elements.

- Plus a lot more.

Protecting the environment and making sure the data is accurate

Protecting the environment and making sure the data is accurateYou need to run some quality control checks after replacing or repairing these parts. Check these things:

- When there are no emissions, the CEMS measures zero correctly, and when there are known emissions, it measures span correctly.

- A calibration drift test checks if the CEMS readings have changed over time.

- Diagnostics: Checking the system to make sure it's working right.

- Check for leaks when you replace an umbilical line (a type of tubing).

- CGA: Cylinder Gas Audit checks the CEMS accuracy with a known gas mixture.

- Verify the formulas and algorithms work if you replace the whole Data Acquisition System (DAS) or change how it processes data.

- Missing data verification: This makes sure the monitoring process doesn't lose data.

Maintaining the accuracy and reliability of the CEMS continuous emission monitoring system is essential. Just like checking a thermometer to make sure it shows the right temperature, it's like making sure the instruments are working. Data collected this way is trustworthy and can be used for regulatory compliance and environmental protection.

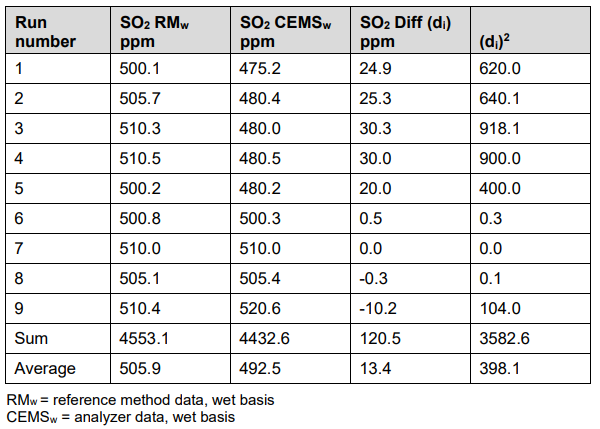

Appendix D - Example calculations of relative accuracy and bias

Experts tested a device to measure sulfur dioxide (SO2) emissions, and the results are in the table. A standard method (RMw) was used to compare the machine's readings (CEMSw). See the numbers in this table:

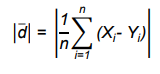

In the example presented in the appendix equation, there's an average difference of 13.4 ppm (parts per million) between the two methods. As a result, the machine's readings were off by 13.4 ppm on average.

This was done using this expression:

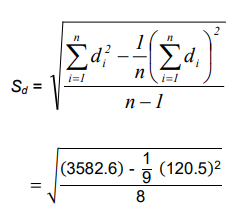

The standard deviation (Sd) measures how spread out the differences are. There's 15.7 parts per million.

Here's the calculation:

Then, the writers used a mathematical method called a confidence coefficient (cc) to say that they're 95% sure the difference between the machine and the standard method is 12.1 ppm. The machine measures sulfur dioxide and it is processed with these calculations it with some calculations to make sure it's accurate.

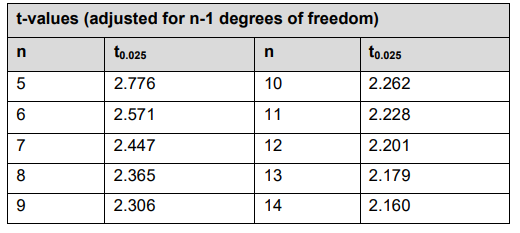

The 12.1 was obtained using the appropriate numbers in this table and the following expression for the confidence coefficient:

cc=t(0.025, in this table) * Sd (15.7, above) / sqrt(n)

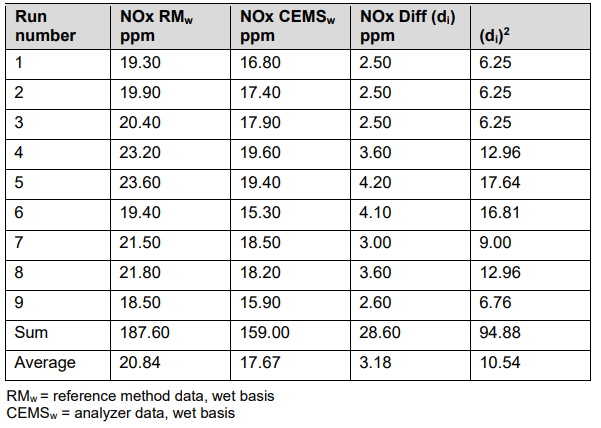

Now for another test, this time measuring nitrogen oxides (NOx). The machine's readings (CEMSw) were compared with a standard method (RMw). Here is a table of the results.

There's an average difference of 3.18 ppm between the two methods for NOx. The machine's readings were off by 3.18 ppm on average.

- Standard deviation (Sd) again measures how spread out the differences are. For NOx, it worked out 0.71 ppm.

- They are 95% confident that the actual difference between the machine and the standard method is within 0.54 ppm based on the "confidence coefficient" (cc) calculation shown above, but this time for NOx.

As a result, the "relative accuracy" (RA) is 17.85% (calculated by adding the absolute average difference to the cc and dividing the result by the average reference method value (20.84 ppm, above)), which is higher than the allowed 10.0%. This setup didn't meet the required accuracy.

The machine met an "alternative relative accuracy specification" of 5 ppm, though.

Bias (B) is how much the machine consistently overreports or underreports.

B = absolute average difference - cc = 3.18 - 0.54

This difference, 2.64 (out of 100) is within the allowed 5.0% range.

Simply put, we checked how well the device under examination measured nitrogen oxides, expressed it with numbers, and found it met some standards, but not others. This example is provided in the original document if you need to see the calculations in full detail.

Appendix E - Flow-to-Load Check

A system's flow rate (like how much stuff moves through a pipe) changes depending on how much work it's doing (the load). When the load changes, the flow rate should stay pretty steady. We can check this with some math.

Integrating data seamlessly by measuring flow rates

Integrating data seamlessly by measuring flow ratesHere's how:

- Use data from a recent test (RATA) to calculate a reference flow-to-load ratio.

- Based on recent data, calculate the average flow-to-load ratio.

- Calculate the difference between the average and reference ratio.

Here's what's important:

- If the difference remains within 10% either direction, It means the flow measurement is consistent over a quarter (three months).

- You might be able to get away with 15% if emissions are low.

- Over a year, if the difference is within 10.0%, it's consistent.

Here's how it works:

- Data from a recent test is used to calculate the reference ratio (Rref).

- Based on recent data, we calculate the average ratio (Rh).

- We calculate the absolute percentage difference (E) between Rref and Rh.

Here's an example:

- From a recent test, the reference ratio (Rref) was 4.96 (industrial units).

- Based on recent data, the average ratio (Rh) is 4.77 (industrial units).

- There's an absolute percentage difference (E) of 3.83%.

- Because the difference is within acceptable limits, the flow measurement is consistent.

In industrial operations, this process makes sure that the amount of stuff flowing through pipes stays consistent as the workload changes. Consistency means the CEMS continuous emission monitoring system equipment is working.

Your CEMS Quality Assurance Partner

CEMS Audits are mandatory in Alberta to ensure compliance with the CEMS Code. Calvin Consulting Group Ltd. helps companies navigate audits, fix deficiencies, and implement corrective action plans. Where needed, we offer comprehensive training. Why Us?

- Our industry-trained professionals help you make sure the Alberta CEMS Code is followed.

- CEMS Audit Corrective Action Plans help you to quickly fix deficiencies.

- CEMS Training Services provide needed training for CEMS staff.

- Complying with Alberta Environment and Protected Areas regulations.

Contact us at:

...if you need help complying with Alberta Environment standards.

CEMS: Definitions, Tests, and Quality Control

At Calvin Consulting, we simplify CEMS practices from defining terms to conducting gas stratification tests. Ensure a consistent flow-to-load ratio, essential to industrial operations' reliability, and navigate regulatory compliance challenges.

Clean air is our Passion...Regulatory Compliance is our Business.

Learn the ins and outs of CEMS with definitions, gas stratification tests, and quality control checks after component changes.

The guide provides an understanding of how to maintain reliable and compliant continuous emission monitoring systems, from verification of emissions accuracy to other consistencies.

Do you have concerns about air pollution in your area??

Perhaps modelling air pollution will provide the answers to your question.

That is what I do on a full-time basis. Find out if it is necessary for your project.

Have your Say...

on the StuffintheAir facebook page

Other topics listed in these guides:

The Stuff-in-the-Air Site Map

And,

Thank you to my research and writing assistants, ChatGPT and WordTune, as well as Wombo and others for the images.

OpenAI's large-scale language generation model (and others provided by Google and Meta), helped generate this text. As soon as draft language is generated, the author reviews, edits, and revises it to their own liking and is responsible for the content.

New! Comments

Do you like what you see here? Please let us know in the box below.