- Air Homepage

- Alberta Air Quality

- How to Improve Data Quality

- High Volume Air Sampler

The Art of High Volume Air Sampler Calibration

Here's something you should check out...this page on the maintenance of high volume air samplers and alternative equipment does this:

- Provides an overview of the calibration process for continuous ambient air analyzers and meteorological sensors, which are essential for monitoring air quality and the environment.

- Describes how to calibrate different types of analyzers and sensors, including ozone, carbon monoxide, nitrogen oxides, sulfur dioxide, hydrogen sulfide, PM2.5, PM10, wind speed, wind direction, temperature, humidity, and pressure.

- Contains examples, diagrams, tables, and formulas to explain calibration methods and calculations, such as gas phase titration, dynamic dilution, orifice calibration, flow rate measurement, and span factor calculation.

- Calibration tips, including choosing the right calibration standards, checking for leaks, adjusting for ambient conditions, and documenting calibrations

It summarizes the details outlined in the 7th chapter of the Alberta Air Monitoring Directive (Sections 7 to 11) for an easier read than the original document. See also, the first several sections of Chapter 7, summarized on this page.

Air Sampler and Analyzer Calibration Code and Precision Rules - Is there a certain number of orifice unit steps, regression slopes, and correlation coefficients required for a legally valid air sampler calibration? Find out how AMD calibrates Hi-Vols and continuous analyzers, with mandatory acceptance limits and rules for data correction.

Here is a list of all chapter summaries for you.

7.0 Calibration of High Volume air Samplers

High volume air samplers:

Frequency of calibration:

- Every three months, calibrate.

Methods of calibration:

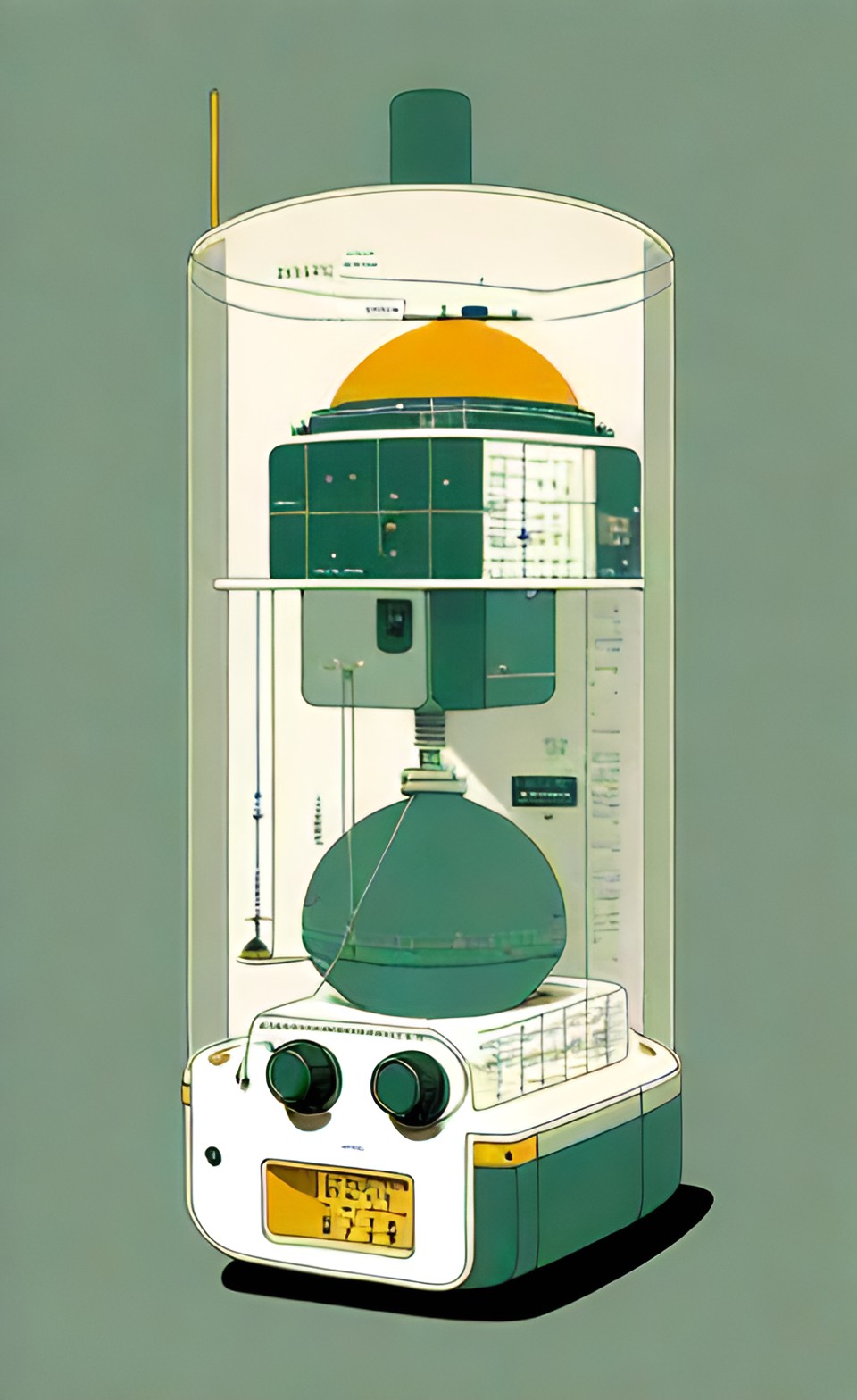

- Cal 7-E specifies the calibration method.

Follow this list

Follow this list- You can also use other calibration methods authorized in writing by the Director.

7.1 Orifice Calibration Unit

Use an orifice calibration unit to calibrate a flow recorder:

The prerequisite is:

- Make sure the orifice calibration unit is calibrated against the positive displacement primary standard.

Steps for calibration:

- Connect the orifice calibration unit to the primary standard.

- Put a high volume blower on the exhaust of the primary standard.

- The pressure tap on the orifice calibration unit should be connected to a differential manometer.

- Variate blower operation for different constant airflows, recording manometer readings.

- Adjust for volume increase due to pressure drop at the inlet of the primary standard.

- Connect a second differential manometer to the primary standard.

- During constant airflow measurements, measure the true inlet pressure.

- Check the pressure and temperature of the air.

- Make sure the measured air volume is right.

- Get the true airflow rate, Q.

- Plot the differential manometer readings against Q for the orifice unit.

- Calibrate the high volume air sampler with the calibrated orifice unit.

7.2 High Volume Air Sampler Calibration

Follow these steps to calibrate a high volume sampler.

Analyses and calibrations

Analyses and calibrationsHow it works:

- Clean the filter on the high volume air sampler.

- Make sure you run for five minutes.

Adjusting the flow recorder:

- Adjust the flow recorder to 65% of full scale.

- Make sure the adjusting mechanism is sealed so it can't be changed easily.

Calibration prep:

- Turn off the motor.

- Filter it out.

Calibration of orifices:

- Replace the filter with the orifice calibration unit.

- Run the high volume sampler at different constant airflows (usually six, including one filter and five load plates).

- Use the differential manometer on the orifice calibration unit to take readings.

Recording data:

- For each airflow, record the flow recorder readings.

- Check the temperature and pressure of the atmosphere.

Plotting and conversion:

- Calculate cubic meters per minute (Q) from differential manometer readings.

- Graph flow recorder readings against Q.

Here's more info:

- Appendix I has detailed calculations for high volume air sampler calibration.

8.0 Calibration of Other Analyzers

Calibration methods that aren't explained in the Air Monitoring Directive (AMD) Calibration Chapter (Chapter 7) need written permission from the Director.

9.0 Calibration Acceptance Limits

It's important to meet certain criteria when calibrating air monitoring instruments. Here's how it works:

Here's what you need:

- The calibration results should meet or exceed the specified acceptance limits.

- Corrective action must be taken if results don't meet requirements.

The calibration curve looks like this:

- At least three concentrations of the gas being measured and a calibration zero air source are used for each calibration.

- Compliance with acceptance limits is determined by least square regression.

Good air monitoring instruments meet strict criteria.

Good air monitoring instruments meet strict criteria.Criteria for verification/calibration (Table 2):

Parameters for gases:

- Check zero: ≤ ±3% of full scale

- Check the span: ≤ ±10%

- Verification/calibration at multiple points:

- It's within 10% of the least squares regression slope (0.9-1.10)

- The correlation coefficient is 0.995

Particulates:

- Check the flow, leak, temperature, and pressure within the manufacturer's specs.

Wind direction:

- Observe 10° from compass for alignment

Weather (except winds):

- 15% from audits

- Digital calibration data points:

- Averaging from 1 second to 5 minutes (300 seconds).

- For accuracy and stability, calibration results should be backed up by recorder traces.

Criteria for specific instruments:

- It can't deviate more than 10% from the expected calibration point.

- A deviation from the adjusted slope can't be more than 5%.

- Ideally, the intercept should be within 3% of the analyzer's range.

- The correlation coefficient must be 0.995.

- Dynamic calibration requires accuracy within 2% using a permeation device or dilution calibrator.

10.0 Assessment and Corrective Action

Calibration results that go over acceptable limits are handled like this:

Flags for data:

- When calibration results aren't acceptable, data flags are used.

Exceeded zero or span drift limits:

Measurements are invalid if zero or span drift limits are exceeded:

- Reset ambient measurements to the most recent valid point.

- If there's another valid point related to the issue, it's usually the previous calibration.

- Overdrift could be caused by a lack of time for stabilization, a power outage, or a malfunctioning piece of equipment.

Malfunction or non-operation of the analyzer:

After an analyzer malfunctions or doesn't work:

- If the unadjusted "as found" zero and high point readings don't support data validity, flag it as invalid until the next calibration.

Calibration Limits Correction:

Analyzer performance doesn't meet calibration acceptance limits:

- Make sure analyzers are calibrated and operating within manufacturer's specs.

11.0 Calibration Records

Keeping records:

- All data and calculations related to calibration of each analyzer must be recorded and kept for three years.

Factors that affect electronics:

- Calibration data must also include electronic factors related to calibration results.

- Calibration records should contain relevant data.

System for digital data:

- At least every 30 seconds, digital systems should update calibration data points.

Representation graphically:

- To show the stability of each measurement point, calibration data should be graphed.

Here's what else you need:

- Documentation and record keeping are covered in the Quality Chapter (Chapter 5) of the AMD.

Precision in air quality calibration data.

Precision in air quality calibration data.11.1 Calibration Reports

Contents of the calibration report:

- The Regulator needs details like the location, date, make/model, and serial number of the calibrated analyzer.

- It's important to know the calibration method, calibrator details, calibration conditions (temperature and pressure), and results.

- You should also include correction factors, calibration curves, linear regression analysis, and who did the calibration.

Keeping records:

- At the continuous ambient air monitoring station, the person responsible should keep copies of calibration reports.

The resources are:

- The AMD website has calibration report templates and an example of a calibration report in Appendix J.

Reporting requirements:

- Check out the AMD's Reporting Chapter (Chapter 9) for more details.

With Calvin Consulting Group Ltd., you can breathe easy! Our expert Air Quality Monitoring services help you ensure precision through meticulous calibration and audit consultation. Since 2007, we've developed over 200 effective Quality Assurance Plans (QAPs) for Continuous Emissions Monitoring Systems (CEMS) and Air Monitoring Directives (AMD).

Calvin Consulting: Why Should You Choose Us? Expertise.

Get in touch with us at

Calvin Consulting Group Ltd. lets you relax with confidence.

Get a glimpse of high volume air sampler calibration, where quarterly precision dances with orifice units.

Find out how to cleanse filters and adjust flow recorders, so your readings are accurate. The calibration journey extends to acceptance limits, scrutinizing gases, particulates, and weather factors.

Watch how deviations are flagged, data integrity is preserved, and records are meticulously maintained in air monitoring.

Do you have concerns about air pollution in your area??

Perhaps modelling air pollution will provide the answers to your question.

That is what I do on a full-time basis. Find out if it is necessary for your project.

Have your Say...

on the StuffintheAir facebook page

Other topics listed in these guides:

The Stuff-in-the-Air Site Map

And,

Thank you to my research and writing assistants, ChatGPT and WordTune, as well as Wombo and others for the images.

OpenAI's large-scale language generation model (and others provided by Google and Meta), helped generate this text. As soon as draft language is generated, the author reviews, edits, and revises it to their own liking and is responsible for the content.

New! Comments

Do you like what you see here? Please let us know in the box below.