- Air Homepage

- Alberta Air Quality

- Prevention of Air Pollution

- Air Emission Sources

Air Emission Sources and Industrial Stacks

It's possible you'll be in charge of your company's Annual Emissions Inventory Report (AEIR). We start by identifying, classifying, and describing industrial air emission sources.

Stack Audit: Mastering AEIR Release Point Data - Do you know the exact SCC Code, exit velocity, and Kelvin Temperature for every smokestack at your facility? Identify every industrial release point, locate it, and detail it for a compliant Annual Emissions Inventory Report without risking penalties

Classifying, identifying, and detailing air pollution.

Classifying, identifying, and detailing air pollution.Compiling your Annual Emissions Inventory Report requires these steps. Learn how to categorize release points and detail essential parameters like stack height and exit velocity.

Also, learn about regulatory air quality dispersion modeling and a bit about how to anticipate emergency situations and release points that might be added later. To ensure compliance with environmental standards and track emissions accurately, you might have to overcome regulatory hurdles and handle industry trends. Your facility can meet regulatory requirements and maintain environmental sustainability with the right effort.

Keeping track of industrial emissions requires mastering the Annual Emissions Inventory Report (AEIR). By identifying, classifying, and describing air emission sources, you can manage and report emissions data effectively.

You'll be able to navigate regulatory requirements, anticipate challenges, and maintain environmental sustainability if you use the AEIR process and need to see how important emissions reporting is.

6.0 - Air Emission Sources release point information

It's essential to uncover critical release point information to understand air emission sources within your industrial operation.

6.1 - Identify release points and emitted substances

We're going to identify the different places within your industrial operation where substances are released into the air in this step of the AEIR (Annual Emissions Inventory Report). Also, we'll figure out what these points emit to the atmosphere.

You'll need to know about identification of release points and substances. There are specific spots in your industrial operation where chemicals are released into the air. They're typically smokestacks or vents.

Compliance with environmental standards,

Compliance with environmental standards,Release types are categorized as either "air emission release points" or "air emission non-point sources." This helps us figure out where emissions come from.

There are a lot of additional information we need to know about each release point, like what units, processes, equipment, and pollution controls are associated with it. We can get a complete picture of emissions by working through these details.

If you have an EPEA (Environmental Protection and Enhancement Act) approval for your industrial operation, you'll know which sources are allowed to release substances into the air. Some sources might get grouped together for other regulatory considerations, but we'll separate them for AEIR processing and submissions.

Regulatory dispersion modeling in your approval application can help you identify these release points. The assessment report is likely to include a map showing where emissions come from.

AEIRs must identify and describe every authorized release point, except those decommissioned before 2018. It's still important to list decommissioned release points with zero hours of operation and no emissions, even though they've been shut down.

Identifying Substances: We also need to figure out what each release point emits. Your EPEA approval, your approval/renewal application, or even your monitoring and reporting data might have this information.

AEIRs from previous years: You can use past reports to identify the substances released by each point if this isn't your first year reporting. However, things might change over time, so keep that in mind. Modifications might be needed.

AEIRs need to include emergency and standby equipment even if it's only used occasionally. However, they might not need detailed reporting if their emissions are very, very low.

Future Planned Release Points: If you have new release points planned and they're authorized in your EPEA approval, include them in your AEIR. You'll also need included their expected emissions in your report.

In this step (officially 6a), we're going to find out where your industrial operation releases stuff in the air and what it is. Maintaining environmental standards and keeping track of emissions depends on it. Step 6b is about...

6.2 - Gathering information on release points

In this step, we're digging deeper into release points in your industrial operation. Here's how it works and how to identify release points.

In the AEIR (Annual Emissions Inventory Report), there are specific requirements outlined in Clause RC 7-L. There are mandatory and optional fields on the AEIR Form.

Release points are classified as follows:

- There are two types of release points: "air emission release points" and "non-point air emission sources sources."

- Smokestacks and vents are examples of air emission release points.

What do you need for each release point? For each release point, you need to fill out the AEIR Form. Information like classification, operation status, installation and decommission dates, location, stack parameters, etc.

Operating status of release points,

Operating status of release points,

What about your future release points? When you have approval for future release points that haven't been built or aren't yet operating, you still have to fill out worksheet 2.0 with the available info. Information like location, source parameters, equipment, operating periods, and emissions can be included here.

Examples of key information fields:

1 - Operating or approved future release points: This field asks if your industrial operation has any operating or approved future release points.

2 - It's where you give each release point a simple name that describes what it is, like "Boiler 1 Stack."

3 - This field requires you to enter a formal designation for the release point, usually in your EPEA approval. A unique identifier like "H-5503A/B."

4 - A release point can have an optional additional description, like what it's connected to.

Source Classification Code (SCC): You need to identify the most appropriate SCC for the release point. The SCC is a standardized way to categorize emission sources. There are four levels and they help group similar sources together.

Release Point Considered Negligible: Indicate whether the release point is considered negligible for the inventory year. The AEIR Form still needs to identify these negligible air emission sources, but they don't have to report detailed emissions.

Operating Status: Select the release point's operating status for the inventory year, like "Operating," "Temporarily shut-down," "Decommissioned," or "Not yet constructed/operating." If the release point is running, you can choose from options like "Normal," "Start-up," "Turnaround," "Upset," "Low Annual Output," and "High Annual Variability."

Specify the phase the release point is in, especially if your industrial operation has multiple phases. Then enter the year the stack/vent was installed, provide the year the release point started and estimate how many hours the release point operated during the inventory year.

Decommission Date (if applicable): If the release point was decommissioned, enter it here. If you think the release point will be shut down permanently in the future, give an estimate.

Approved Future Source: Indicates if the release point is approved, but not yet built. If it's a future source, specify the first year it's expected to operate. Tracking emissions and ensuring compliance with environmental standards require accurate reporting of release point information.

We're affected by air pollution,

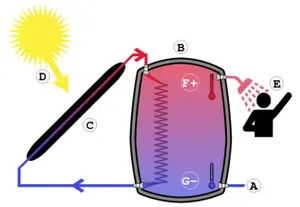

We're affected by air pollution,For the locations of air emission sources and Source Parameters, this section talks about where and how your industrial release points are located. Start with Information about the location:

- Base Elevation (m ASL): This is the height above sea level where the release point is located.

- The Release Point Latitude (Decimal, NAD 83) is the geographic latitude coordinate of the release point.

- Longitude (Decimal, NAD 83): Like latitude, this is the longitude coordinate of the release point.

Next you use this information about the source parameters:

- Minimum Height Above Grade (m) (if applicable): If the release point has a minimum height, it goes here (in meters.) You can leave this blank if you don't want to.

- Actual Release Point Height (m): This field needs the height of the stack or vent from ground level. Use the proposed/modeled height for future air emission sources.

- The Release Point Diameter (m) is the inner physical diameter of the stack or vent. Here's where emissions come out.

- Average Exit Velocity (m/s): Enter the average speed at which emissions exit the stack or vent.

- If there's a maximum exit velocity that's different from the average, you put it here.

- Release Point Minimum Exit Velocity (m/s) (if applicable): Like the maximum, if there's a minimum exit velocity that's different from the average, enter it.

- Average Exit Temperature (K) at Release Point: This is the average temperature of the emissions as they leave the stack.

- Maximum Exit Temperature (K) (if applicable): If there's a maximum temperature, enter it.

- Temperature at Release Point Minimum Exit (K) (if applicable or specified in approval): Like the maximum, if there's a minimum temperature, it's entered here in Kelvin.

Information about the stack:

- Does the release point bypass the stack? (Y/N): Indicates if this release point is a bypass.-

- Does the release point have a rooftop associated with it? (Y/N): Tells if the release point is on a roof.-

- Does building downwash affect the release point? (if known from previous studies): If you know if building downwash might affect the release point, answer here. (Y/N)-

- Is there a rain cap on the release point? (Y/N): If the release point has a rain cap.-

- Does release point have a non-

- vertical release? (Y/N): Specifies whether the release point is horizontal.

You need this info to air emission sources emissions accurately and make sure you're in compliance. Do you have an EPEA approval for your Alberta industrial facility?

At Calvin Consulting Group Ltd...

Our experts can help you prepare and submit your Annual Emissions Inventory Report (AEIR).

We know how important it is to meet AEIR thresholds by September 30. We make sure you report release points and contaminants accurately, which is crucial for environmental compliance.

Send us an email to streamline your AEIR submission.

We'll help you identify release points, fill out the AEIR Form, and include future releases. Calvin Consulting Group Ltd. ensures compliance and accuracy.

Clean air is our Passion...Regulatory Compliance is our Business.

Learn how to identify, classify, and describe air pollution sources within industrial operations for the Annual Emissions Inventory Report.

We'll talk about smokestacks and vents, classification criteria, required details, and regulatory dispersion modeling. We're going to explore substance identification and parameters that are needed for accurate emissions assessment.

Do you have concerns about air pollution in your area??

Perhaps modelling air pollution will provide the answers to your question.

That is what I do on a full-time basis. Find out if it is necessary for your project.

Have your Say...

on the StuffintheAir facebook page

Other topics listed in these guides:

The Stuff-in-the-Air Site Map

And,

Thank you to my research and writing assistants, ChatGPT and WordTune, as well as Wombo and others for the images.

OpenAI's large-scale language generation model (and others provided by Google and Meta), helped generate this text. As soon as draft language is generated, the author reviews, edits, and revises it to their own liking and is responsible for the content.

New! Comments

Do you like what you see here? Please let us know in the box below.